Gain Understanding Into The Best Pasteurization Options For Your Production Requires-- Ascertain Which Remedy Is The Perfect Fit For Your Procedures

When deciding in between Tunnel pasteurizers and batch pasteurizers, you might ask yourself which alternative matches your manufacturing needs finest. Factors like production quantity, running prices, and item quality all come into play when making this important choice. Recognizing the special advantages and restrictions of each system can assist you make an educated choice that aligns with your business objectives and top quality requirements. Keep tuned to uncover essential understandings that will guide you in selecting the ideal pasteurization solution for your details needs.

## Efficiency and Throughput

When contrasting Tunnel pasteurizers to batch pasteurizers in terms of efficiency and throughput, the former typically outmatches the latter in constant handling capacities. Tunnel pasteurizers are developed for constant handling, permitting a continuous circulation of products through the system. This configuration makes it possible for greater throughput rates compared to batch pasteurizers, which run in cycles with stops in between each batch.

The continual circulation in Tunnel pasteurizers leads to a much more effective processing technique, reducing traffic jams and making the most of production output.

In addition, Tunnel pasteurizers use better temperature control throughout the entire procedure. The constant temperature level degrees kept in Tunnel pasteurizers make sure consistent pasteurization of items, boosting effectiveness and quality.

In contrast, batch pasteurizers might experience temperature changes in between sets, potentially impacting the total efficiency of the pasteurization process.

## Price Analysis

To further assess the practicality of Tunnel pasteurizers versus batch pasteurizers, an important facet to consider is the price evaluation. Tunnel pasteurizers normally have a higher ahead of time cost as a result of their automated and continual operation, however they provide significant cost savings in labor prices over time. On the other hand, batch pasteurizers have a reduced first financial investment but might require more manual work, increasing operational costs over time.

When examining the cost-effectiveness of each choice, it's essential to think about not just the purchase price but additionally ongoing expenditures like energy consumption, upkeep, and labor. Tunnel pasteurizers have a tendency to be more energy-efficient because they run continually and make use of warm healing systems. batch pasteurizers, while simpler in style, may consume extra power throughout each batch handling cycle.

Ultimately, view in between Tunnel and batch pasteurizers will certainly depend on your manufacturing quantity, spending plan constraints, and long-term operational goals. Conducting a thorough expense analysis taking into consideration both immediate and long-term expenses will certainly aid you establish the most economical remedy for your certain demands.

## Product High Quality and Service Life

For optimum item quality and expanded shelf life, the option between Tunnel pasteurizers and batch pasteurizers plays an essential function in your manufacturing process.

Tunnel pasteurizers are known for their ability to supply consistent and uniform warm circulation throughout the item, making certain that all containers are sterilized successfully. This harmony aids preserve the top quality of your products by reducing the threat of under or over-pasteurization.

On the other hand, batch pasteurizers supply even more adaptability in processing smaller sized quantities of products with differing dishes or ingredients. While this versatility can be useful in specific circumstances, it may also bring about incongruities in pasteurization degrees, potentially affecting item quality and shelf life.

When it comes to service life, the accuracy and control used by Tunnel pasteurizers can help expand the durability of your products by guaranteeing that dangerous microbes are properly removed. This can cause a longer shelf life for your items, eventually benefiting your organization and clients. Think about the specific demands of your products and manufacturing process to determine which pasteurization method straightens finest with your objectives for item high quality and service life.

## Conclusion

Finally, when choosing between Tunnel pasteurizers and batch pasteurizers, it is clear that Tunnel pasteurizers supply remarkable efficiency, throughput, cost-effectiveness, and item top quality. With their continuous handling abilities, far better temperature control, and prolonged shelf life advantages, Tunnel pasteurizers are the recommended choice for numerous food and beverage manufacturers. Make the switch to Tunnel pasteurizers for enhanced results in your manufacturing procedure.

Examine The Various Benefits Of Batch Pasteurizers For Food Suppliers And Figure Out How These Tools Can Enhance Your Production Procedures

When it pertains to enhancing your food manufacturing procedures, batch pasteurizers provide a multitude of benefits worth taking into consideration. From guaranteeing the safety and high quality of your items to enhancing efficiency and uniformity, these equipments hold the secret to an extra efficient operation. However that's simply scratching the surface. By discovering https://thedeepdive.ca/tinley-beverage-conducts-2-4-million-financing-to-support-co-packing-operations/ supplied, you'll uncover a riches of details that can revolutionize the method you approach food production.

## Improved Product Safety And Security and Top Quality

When utilizing batch pasteurizers in your food producing procedure, you can anticipate a considerable improvement in product safety and quality. By using batch pasteurizers, you guarantee that unsafe microorganisms are efficiently gotten rid of from your items, reducing the threat of foodborne diseases.

The precise temperature level control and uniform warm distribution supplied by these pasteurizers guarantee that your products are safely pasteurized without endangering their top quality or preference.

In addition, batch pasteurizers assist in expanding the life span of your items by getting rid of spoilage-causing microorganisms, mold and mildews, and yeasts. This implies that your food products will preserve their quality for longer durations, reducing waste and enhancing consumer satisfaction.

With improved product security and high quality, you can with confidence meet regulative criteria and consumer expectations, building a strong credibility for your brand.

“From Cosmetics to Pharmaceuticals: How Tunnel and Batch Pasteurizers Are Revolutionizing Product Safety”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) October 8, 2024

Article Release for Brewmasters

Article: https://t.co/MBbegEueSw

PRO Engineering / Manufacturing Inc.

414-362-1500

sales@prowm.com

https://t.co/GkQF8BPrG3

Incorporating batch pasteurizers right into your food making procedure is an aggressive action that shows your commitment to delivering safe, premium products to your customers. By buying this technology, you aren't only guarding public health yet likewise boosting the total value of your food products.

## Structured Manufacturing Processes

Occasionally, enhancing your food manufacturing process with batch pasteurizers can bring about streamlined production processes. By integrating batch pasteurizers into your procedures, you can optimize the home heating and cooling cycles, leading to much more effective manufacturing timelines. With accurate temperature control and automated procedures, batch pasteurizers help reduce manual labor demands and lessen the risk of human mistake throughout manufacturing.

Additionally, batch pasteurizers permit regular and repeatable results, making certain that each batch meets the same top quality criteria. This uniformity eliminates the demand for considerable manual tracking and adjustments, conserving time and sources in the long run.

Streamlining your manufacturing processes with batch pasteurizers can likewise lead to boosted general efficiency, allowing you to focus on other elements of your organization.

Additionally, the structured production procedures enabled by batch pasteurizers can help you meet limited deadlines and respond quickly to changes popular. By boosting effectiveness and reducing manufacturing bottlenecks, batch pasteurizers add to a more agile and receptive production operation.

## Extended Shelf Life and Uniformity

Improve the quality and long life of your food with the execution of batch pasteurizers for prolonged life span and uniformity. By making use of batch pasteurizers, you can substantially prolong the life span of your food products. The precise temperature level control and uniform heating offered by batch pasteurizers make certain that damaging germs are removed, expanding the freshness of your products.

Uniformity is key in the food sector, and batch pasteurizers provide a dependable method to accomplish uniform outcomes with each production cycle. By maintaining regular warmth circulation throughout the pasteurization procedure, batch pasteurizers aid you supply items that fulfill the very same high requirements every time. This not just enhances client complete satisfaction however additionally constructs rely on your brand name.

With batch pasteurizers, you can create food items with extended service life while maintaining uniformity in top quality. This twin benefit not just raises the bankability of your products yet also decreases waste, eventually adding to a more reliable and successful operation.

## Final thought

On the whole, batch pasteurizers offer food producers a wide variety of benefits, consisting of improved product security, quality, and uniformity. By enhancing production processes and expanding shelf life, these devices not just boost consumer complete satisfaction however also enhance marketability and success. Welcoming batch pasteurizers can revolutionize food production procedures, offering an one-upmanship in the industry. Make the switch today and experience the countless advantages for yourself.

Explore The Benefits That Batch Pasteurizers Offer To Food Manufacturers And Discover How These Systems Can Improve Your Production Processes

When it pertains to enhancing your food manufacturing processes, batch pasteurizers use a wide variety of benefits worth taking into consideration. From making certain the safety and security and top quality of your items to maximizing effectiveness and consistency, these machines hold the trick to an extra reliable operation. However that's just scratching the surface. By discovering the thorough guide provided, you'll reveal a wealth of details that can transform the method you approach food manufacturing.

## Improved Product Security and High Quality

When using batch pasteurizers in your food producing procedure, you can anticipate a considerable renovation in product safety and security and top quality. By utilizing batch pasteurizers, you make certain that damaging virus are effectively removed from your products, minimizing the risk of foodborne diseases.

The accurate temperature control and uniform heat distribution supplied by these pasteurizers guarantee that your items are safely sterilized without compromising their quality or preference.

In addition, batch pasteurizers aid in prolonging the life span of your items by eliminating spoilage-causing microorganisms, mold and mildews, and yeasts. This indicates that your food things will maintain their quality for longer periods, lowering waste and raising consumer fulfillment.

With boosted item safety and security and quality, you can with confidence fulfill regulative standards and customer assumptions, developing a solid online reputation for your brand.

Integrating batch pasteurizers right into your food making process is an aggressive procedure that demonstrates your commitment to delivering safe, top notch items to your customers. By buying this innovation, you aren't only safeguarding public health yet also enhancing the total worth of your food.

## Structured Production Procedures

Occasionally, improving your food manufacturing procedure with batch pasteurizers can lead to structured production procedures. By incorporating batch pasteurizers right into your operations, you can optimize the home heating and cooling down cycles, causing much more effective manufacturing timelines. With accurate temperature level control and automated procedures, batch pasteurizers help reduce manual labor demands and lessen the danger of human error during manufacturing.

Additionally, batch pasteurizers enable consistent and repeatable outcomes, guaranteeing that each batch fulfills the exact same high quality requirements. This consistency gets rid of the need for considerable hand-operated monitoring and changes, saving time and sources in the future.

Enhancing your manufacturing processes with batch pasteurizers can additionally cause enhanced total efficiency, allowing you to concentrate on other aspects of your organization.

Furthermore, the structured manufacturing processes allowed by batch pasteurizers can assist you meet limited target dates and react swiftly to variations sought after. By enhancing effectiveness and reducing manufacturing traffic jams, batch pasteurizers add to a more nimble and receptive manufacturing procedure.

## Extended Life Span and Consistency

Enhance the top quality and long life of your food with the execution of batch pasteurizers for extended life span and consistency. By making use of batch pasteurizers, you can significantly prolong the life span of your food things. https://finance.yahoo.com/news/tilray-brands-completes-acquisition-craft-143300889.html and consistent heating supplied by batch pasteurizers ensure that dangerous germs are gotten rid of, expanding the quality of your products.

Uniformity is key in the food industry, and batch pasteurizers supply a reputable method to attain uniform outcomes with each production cycle. By preserving consistent warm circulation throughout the pasteurization procedure, batch pasteurizers assist you deliver products that satisfy the same high criteria every time. This not only improves consumer satisfaction however additionally develops count on your brand.

With batch pasteurizers, you can generate food items with prolonged shelf life while maintaining consistency in quality. This dual benefit not just raises the bankability of your products however additionally lowers waste, ultimately contributing to a more effective and rewarding procedure.

## Verdict

Overall, batch pasteurizers provide food makers a wide range of advantages, consisting of improved product safety, high quality, and consistency. By enhancing production processes and expanding life span, these makers not just boost client complete satisfaction but likewise raise marketability and profitability. Welcoming batch pasteurizers can transform food manufacturing procedures, providing a competitive edge in the industry. Make the button today and experience the many benefits on your own.

Enhancing Performance: Enhancing Your Assembly Line With Tunnel Pasteurizers

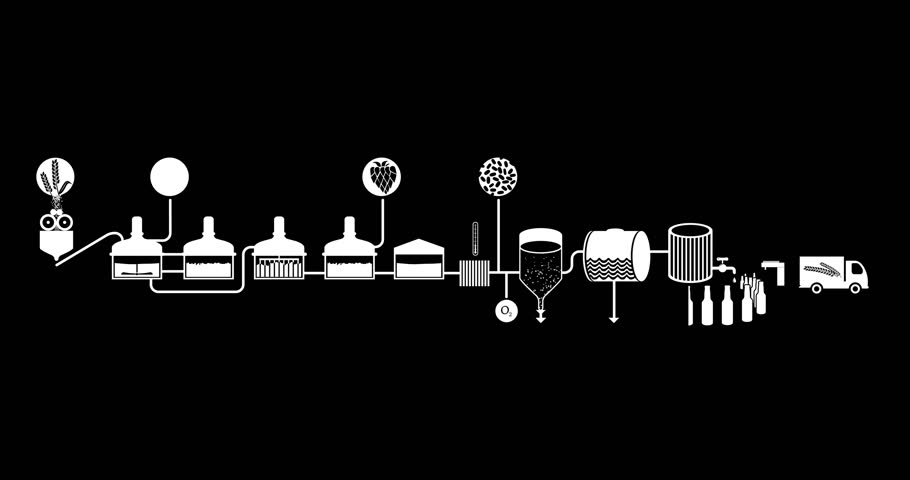

Tunnel pasteurizers are big industrial-scale equipments that warm and amazing drinks in order to eliminate microbes and extend their shelf life. Their effectiveness depends upon precision control.

Numerous beverage companies have actually retrofitted their existing Tunnel pasteurizers with brand-new eco-friendly technologies to attain considerable environmental benefits. These consist of lowered energy consumption, reduced water usage and lowered greenhouse gas exhausts.

1. Boosted Productivity

When you run a brewery, your goal isn't just to remove damaging virus, but likewise to use uniformity in your products. A well-executed pasteurization procedure not just lengthens beer's service life, yet it guarantees that every container of your beer will certainly taste the very same, from your first batch to your last. This is especially essential for craft breweries aiming to bring in health-conscious customers that desire the fizzy goodness of soft drinks.

Tunnel pasteurizers work by bringing bottles and containers up to their desired temperature in stages, holding them there for long enough to exterminate the bacteria that cause spoilage. They then bring them down once again in incremental steps up until they reach room temperature level, preserving taste profiles. By doing this, they not only avoid germs from increasing in the item, yet they likewise decrease energy usage by getting rid of heat loss. These are the kinds of efficiency gains that can add up swiftly.

2. Reduced Waste

As more focus is placed on green manufacturing practices, beverage manufacturers are searching for ways to minimize their waste manufacturing. Tunnel pasteurizers do a terrific task of this, specifically when they are created and built by skilled specialists.

Tunnel pasteurizers make use of a series of sprays to heat up the bottles or containers as they relocate with the maker. This eliminates the need for a big steam tank that eats power and wastes water. Furthermore, Tunnel pasteurizers make use of a water cost savings system to reuse the hot water used in the home heating process, which reduces water and sewer usage.

One more benefit of Tunnel pasteurization is its compatibility with soft drinks, which is a big marketing point for craft brewers that wish to extend their products' life span and make certain uniformity in between batches. Unlike flash pasteurizers, which occasionally have problem with high levels of carbonation, Tunnel units can deal with these bubbly mixtures without breaking a sweat (or a bottle).

3. Much Better Item High Quality

When your beverages are appropriately dealt with in Tunnel pasteurizers, they're safeguarded from harmful bacteria while maintaining their taste profiles. This suggests your mixtures, sodas, acid maintains (like fruits or acids), and health shots can expand their service life without shedding their signature preference.

In order to attain this, tunnels include accurate temperature control and even circulation throughout their numerous phases. In addition, conveyor belt speeds help make certain equal treatment times for each bottle going into the maker. All this assists you ensure quality outcomes each time.

Finally, passages work with carbonated beverages, a growing trend amongst health-conscious consumers seeking fizzy alternatives to sugary sodas. Unlike flash pasteurizers, which can have problem with high-carbonation degrees, Tunnel equipments are developed to handle them.

In addition, retrofitting tunnels with power recuperation systems lowers water use also. By utilizing the recovered water for air conditioning, you'll dramatically reduce your energy intake and greenhouse gas emissions.

4. Decreased Energy Usage

Tunnel pasteurizers are energy-intensive equipments, yet you can lower your power usage by retrofitting them with sophisticated eco-friendly technology. please click the next website page includes solar-powered heating elements that can work on renewable resource resources, lowering dependence on nonrenewable fuel sources and your carbon impact.

One more terrific function of Tunnel pasteurizers is that they work with carbonated beverages, a prominent trend among today's health-conscious consumers. Unlike flash pasteurizers, which often battle with high-carbonation degrees, Tunnel units can take care of these carbonated concoctions easily.

zPasteurAIzer can monitor the efficiency of your present Tunnel pasteurizer by estimating the collected item top quality (PU) value for every set. This allows you to determine if your present temperature level control system is delivering enough warmth treatment in addition to determining any kind of bent spray heads. You can after that readjust the maker settings based upon your recommended PU values, raising manufacturing efficiency while lowering power usage. This is an excellent means to lower your water usage also, aligning your organization with consumer demand for ecologically accountable items.

Boosting Performance: Enhancing Your Production Process Utilizing Tunnel Pasteurization Tools

Tunnel pasteurizers are big industrial-scale devices that heat and awesome drinks in order to eliminate microorganisms and expand their life span. Their effectiveness depends on precision control.

Numerous beverage firms have retrofitted their existing Tunnel pasteurizers with new green innovations to achieve considerable environmental benefits. These include lowered power consumption, lower water use and lowered greenhouse gas exhausts.

1. Enhanced Efficiency

When you run a brewery, your objective isn't just to get rid of damaging virus, but also to provide uniformity in your items. A well-executed pasteurization process not just lengthens beer's life span, yet it guarantees that every bottle of your beer will certainly taste the exact same, from your first batch to your last. This is particularly essential for craft breweries looking to attract health-conscious clients who desire the carbonated goodness of soft drinks.

Tunnel pasteurizers function by bringing containers and containers up to their wanted temperature level in stages, holding them there for enough time to kill off the bacteria that trigger wasting. They after that bring them down once again in incremental steps till they reach area temperature level, protecting preference profiles. By doing this, they not just protect against microorganisms from increasing in the item, but they additionally minimize power consumption by removing warmth loss. These are the sort of performance gains that can build up swiftly.

2. Decreased Waste

As more focus is put on environment-friendly production practices, beverage suppliers are trying to find means to minimize their waste production. Tunnel pasteurizers do a terrific work of this, particularly when they are designed and developed by skilled experts.

Tunnel pasteurizers use a series of sprays to warm the bottles or containers as they move through the device. This eliminates the need for a big steam storage tank that consumes power and wastes water. Additionally, Tunnel pasteurizers utilize a water cost savings system to reuse the warm water utilized in the home heating process, which decreases water and sewer use.

One more advantage of Tunnel pasteurization is its compatibility with carbonated drinks, which is a large selling point for craft brewers that wish to prolong their items' shelf life and ensure consistency in between sets. Unlike flash pasteurizers, which occasionally deal with high degrees of carbonation, Tunnel units can handle these bubbly concoctions without breaking a sweat (or a bottle).

3. Much Better Item Quality

When your beverages are effectively dealt with in Tunnel pasteurizers, they're protected from dangerous microorganisms while protecting their taste accounts. This means your mixtures, sodas, acid maintains (like fruits or acids), and health shots can extend their life span without losing their trademark preference.

In order to accomplish this, passages feature accurate temperature control and also circulation throughout their several stages. Furthermore, https://www.farmanddairy.com/news/lawmakers-want-to-extend-shelf-life-of-pa-milk/656612.html help guarantee equal treatment times for each and every container entering the device. All this helps you ensure top quality outcomes whenever.

Finally, tunnels work with carbonated beverages, a growing pattern amongst health-conscious customers trying to find carbonated options to sweet sodas. Unlike flash pasteurizers, which can deal with high-carbonation degrees, Tunnel devices are created to manage them.

Moreover, retrofitting passages with energy recuperation systems lowers water use too. By utilizing the retrieved water for air conditioning, you'll considerably reduce your energy intake and greenhouse gas exhausts.

4. Minimized Energy Consumption

Tunnel pasteurizers are energy-intensive makers, yet you can lower your power usage by retrofitting them with advanced environment-friendly technology. This includes solar-powered heating elements that can run on renewable energy sources, lowering dependence on fossil fuels and your carbon footprint.

https://www.foodsafetynews.com/2017/08/another-california-dairy-cleared-for-retail-sales-of-raw-milk/ of Tunnel pasteurizers is that they work with carbonated beverages, a preferred fad amongst today's health-conscious customers. Unlike flash pasteurizers, which in some cases have problem with high-carbonation degrees, Tunnel systems can take care of these carbonated concoctions effortlessly.

zPasteurAIzer can check the effectiveness of your current Tunnel pasteurizer by approximating the gathered item top quality (PU) worth for each and every set. This allows you to identify if your current temperature control system is supplying sufficient warmth treatment in addition to recognizing any bent spray heads. You can after that change the machine setups based upon your preferred PU worths, raising manufacturing efficiency while lowering power consumption. This is a wonderful way to reduce your water intake as well, aligning your service with consumer demand for environmentally liable items.

Enhancing Productivity: Improving Your Manufacturing Procedures With Tunnel Pasteurization Solution

Tunnel pasteurizers are big industrial-scale equipments that warmth and great beverages in order to eliminate microbes and extend their life span. Their performance relies on accuracy control.

A number of beverage business have retrofitted their existing Tunnel pasteurizers with new environment-friendly modern technologies to attain significant ecological advantages. https://www.cmaj.ca/content/re-double-insurance-holder-pasteurization-and-human-milk-itself-guarantee-safety include lowered power consumption, lower water usage and lowered greenhouse gas discharges.

1. Raised Efficiency

When you run a brewery, your goal isn't simply to eliminate hazardous virus, but also to use uniformity in your items. A well-executed pasteurization procedure not just lengthens beer's service life, however it ensures that every container of your beer will certainly taste the same, from your first set to your last. This is specifically crucial for craft breweries looking to draw in health-conscious clients that desire the carbonated benefits of carbonated drinks.

Tunnel pasteurizers work by bringing containers and cans as much as their desired temperature level in stages, holding them there for long enough to exterminate the microbes that create wasting. They after that bring them down again in step-by-step actions until they reach room temperature level, protecting preference accounts. By doing this, they not only stop germs from multiplying in the item, however they additionally minimize energy usage by removing warm loss. These are the sort of performance gains that can add up rapidly.

2. Lowered Waste

As even more emphasis is positioned on green manufacturing methods, beverage suppliers are searching for methods to decrease their waste manufacturing. Tunnel pasteurizers do a great task of this, especially when they are designed and built by skilled specialists.

Tunnel pasteurizers use a series of sprays to heat the bottles or cans as they move with the equipment. This removes the need for a huge steam tank that eats power and drainages. Additionally, Tunnel pasteurizers make use of a water savings system to recycle the hot water utilized in the home heating process, which decreases water and sewage system usage.

An additional benefit of Tunnel pasteurization is its compatibility with carbonated drinks, which is a big marketing factor for craft brewers who intend to expand their products' service life and make sure consistency in between sets. Unlike flash pasteurizers, which often have problem with high levels of carbonation, Tunnel units can manage these bubbly concoctions without breaking a sweat (or a container).

3. Much Better Product Top Quality

When your drinks are properly treated in Tunnel pasteurizers, they're secured from harmful microorganisms while protecting their taste profiles. This implies your mixtures, sodas, acid maintains (like fruits or acids), and wellness shots can extend their shelf life without losing their signature preference.

In order to accomplish this, passages include specific temperature control and also distribution throughout their numerous stages. Additionally, conveyor belt speeds assist make sure equal therapy times for every bottle entering the device. All this aids you ensure quality results whenever.

Ultimately, passages work with carbonated beverages, an expanding pattern amongst health-conscious customers searching for fizzy choices to sweet sodas. Unlike flash pasteurizers, which can deal with high-carbonation levels, Tunnel makers are made to handle them.

In addition, retrofitting tunnels with energy recovery systems decreases water usage as well. By utilizing the retrieved water for air conditioning, you'll substantially reduce your power consumption and greenhouse gas discharges.

4. Reduced Energy Usage

Tunnel pasteurizers are energy-intensive devices, however you can reduce your power consumption by retrofitting them with advanced green modern technology. This includes solar-powered heating elements that can run on renewable energy resources, reducing reliance on nonrenewable fuel sources and your carbon footprint.

One more terrific function of Tunnel pasteurizers is that they work with carbonated beverages, a preferred pattern among today's health-conscious customers. Unlike flash pasteurizers, which sometimes fight with high-carbonation degrees, Tunnel units can handle these carbonated mixtures with ease.

zPasteurAIzer can check the effectiveness of your current Tunnel pasteurizer by approximating the collected product high quality (PU) value for every batch. This allows you to figure out if your present temperature level control system is providing enough warm treatment as well as determining any kind of curved spray heads. You can after that readjust the maker settings based upon your recommended PU worths, increasing production effectiveness while decreasing energy intake. This is a wonderful means to cut down your water usage as well, straightening your company with consumer demand for ecologically accountable products.

Enhancing Efficiency: Enhancing Your Production Process Making Use Of Tunnel Pasteurization Tools

Tunnel pasteurizers are huge industrial-scale makers that warmth and cool beverages in order to kill microbes and expand their shelf life. Their effectiveness depends on precision control.

A number of drink business have actually retrofitted their existing Tunnel pasteurizers with new environment-friendly modern technologies to accomplish considerable environmental benefits. These consist of lowered power usage, reduced water usage and lowered greenhouse gas emissions.

1. Increased Productivity

When you run a brewery, your objective isn't just to remove dangerous virus, but also to supply consistency in your items. A well-executed pasteurization process not only prolongs beer's life span, yet it guarantees that every bottle of your beer will taste the very same, from your first batch to your last. This is specifically important for craft breweries looking to bring in health-conscious consumers who desire the fizzy goodness of soft drinks.

Tunnel pasteurizers work by bringing containers and containers as much as their wanted temperature in phases, holding them there for long enough to kill off the microbes that trigger wasting. They then bring them down once again in step-by-step actions up until they reach room temperature level, maintaining taste profiles. By doing this, they not just avoid germs from multiplying in the product, but they also decrease power consumption by getting rid of warmth loss. These are the sort of efficiency gains that can build up promptly.

2. Reduced Waste

As more focus is positioned on environment-friendly production techniques, beverage manufacturers are looking for means to minimize their waste production. Tunnel pasteurizers do a terrific task of this, specifically when they are made and developed by seasoned experts.

Tunnel pasteurizers use a series of sprays to heat up the bottles or containers as they move through the equipment. This removes the requirement for a big steam storage tank that consumes power and wastes water. In addition, Tunnel pasteurizers utilize a water financial savings system to recycle the hot water utilized in the heating procedure, which decreases water and sewage system use.

One more benefit of Tunnel pasteurization is its compatibility with soft drinks, which is a large marketing factor for craft brewers that wish to prolong their products' shelf life and ensure consistency between sets. Unlike flash pasteurizers, which occasionally have problem with high levels of carbonation, Tunnel systems can deal with these bubbly concoctions without breaking a sweat (or a bottle).

3. Much Better Product Top Quality

When your beverages are effectively treated in Tunnel pasteurizers, they're safeguarded from hazardous germs while preserving their taste profiles. https://www.prnewswire.com/news-releases/blue-diamond-growers-celebrates-grand-opening-of-new-salida-manufacturing-facility-unveils-industry-first-technology-for-new-pasteurization-line-300919823.html suggests your mixtures, sodas, acid preserves (like fruits or acids), and wellness shots can prolong their life span without losing their signature taste.

In order to achieve this, passages feature precise temperature control and also circulation throughout their multiple phases. Additionally, conveyor belt speeds help guarantee equivalent therapy times for every container going into the device. All this aids you guarantee high quality outcomes every single time.

Lastly, passages are compatible with carbonated beverages, an expanding trend among health-conscious consumers trying to find fizzy choices to sweet soft drinks. Unlike flash pasteurizers, which can battle with high-carbonation levels, Tunnel devices are developed to manage them.

Moreover, retrofitting passages with energy healing systems reduces water use also. By using the retrieved water for cooling, you'll significantly reduce your power usage and greenhouse gas discharges.

4. Decreased Power Usage

Tunnel pasteurizers are energy-intensive machines, but you can reduce your energy consumption by retrofitting them with innovative environmentally friendly modern technology. This consists of solar-powered burner that can work on renewable resource sources, reducing reliance on nonrenewable fuel sources and your carbon impact.

An additional excellent function of Tunnel pasteurizers is that they work with carbonated beverages, a popular pattern amongst today's health-conscious consumers. Unlike flash pasteurizers, which sometimes struggle with high-carbonation levels, Tunnel units can deal with these fizzy concoctions with ease.

"Elevating Co-Packing Partnerships: The Features and Benefits of Investing in New Tunnel Pasteurizers or Batch Pasteurizers"

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) December 26, 2023

Article Release by PRO Engineering / Manufacturing Inc.

Click for article: https://t.co/efrL1fLtBp

PRO Engineering / Manufacturing Inc.

414-362-1500

zPasteurAIzer can monitor the performance of your current Tunnel pasteurizer by approximating the collected product top quality (PU) value for each and every set. This enables you to identify if your present temperature control system is supplying sufficient heat therapy along with recognizing any bent spray heads. You can after that change the device settings based upon your favored PU worths, raising production efficiency while decreasing energy consumption. This is an excellent method to reduce your water consumption too, aligning your service with consumer demand for ecologically accountable items.

Guaranteeing High Quality: The Feature Of Tunnel Pasteurizers In Drink Manufacturing

Tunnel pasteurizers are essential for getting rid of wasting microorganisms and controlling pathogenic microorganisms in beverages like beer, milk, juice and sodas. They heat and after that cool down the product to remove these germs.

They likewise save power, water and lower co2 emissions aligning production with sustainability targets. Picking a passage pasteurization system that's engineered by skilled professionals like PRO guarantees precision in the timing and temperature degrees used in each stage.

Microbiological Control

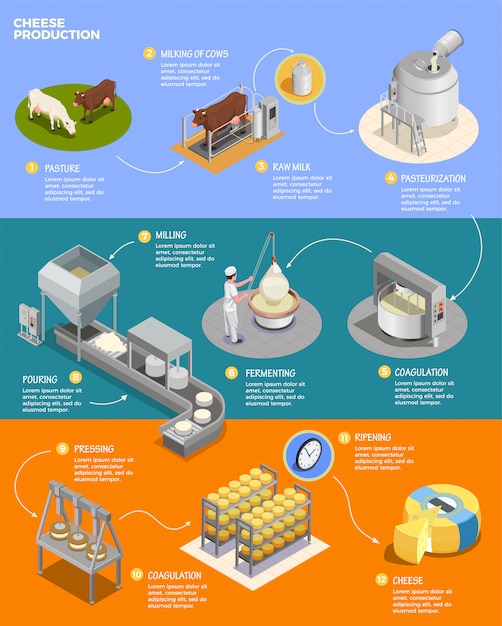

The control of bacteria in food and beverages is necessary to avoid putridity, food poisoning, and various other adverse impacts on the final product. Microbial contaminations can be caused by pathogenic (i.e., disease-causing) microorganisms or spoilage fungis. Techniques for controlling microbial contamination can consist of physical, chemical, or biological approaches. Those that eliminate or inactivate microorganisms are called sanitation, sanitation, antisepsis, and sanitization.

Microbial fatality curves, which illustrate the logarithmic decline of living microbes after direct exposure to a therapy method, are critical devices for determining the efficiency of a microbial control approach. The time it takes for a method to yield a 1-log decrease in the microbial population is described the decimal reduction value, or D-value.

To guarantee precise microbial evaluation outcomes, it is very important to keep the example and the examination system itself free of contamination. Utilizing a microbiological incubator that offers a reliable 140 oC purification cycle, such as the Thermo Scientific Heratherm Incubator, can aid eliminate cross-contamination in between examples and screening devices, therefore ensuring that the outcomes of any kind of microbial examinations are valid.

Stability

When it pertains to keeping your drink steady, Tunnel pasteurizers can do a great deal of job. These equipments give both the bottle or can and its components a warm treatment-- which assists expand service life while protecting those specialized active ingredients craft breweries enjoy a lot.

In a common Tunnel pasteurizer, the bundle and fluid are shared through numerous areas that slowly cozy and cool down the item. Each spray head delivers water at different temperatures, and the nozzles are positioned to maximize insurance coverage with a minimum of thermal stress.

The timing and temperature of each spray are based on a beverage-specific number of pasteurization units (PU) called for to eliminate any microorganisms in the container. The progressive nature of home heating likewise minimizes carbonation loss in low-carbonated drinks.

Safety

Tunnel pasteurizers can be utilized to heat deal with a beverage also after it has been loaded into bottles and cans. This can aid lengthen shelf security for carbonated beverages without compromising their fizz.

https://www.foodsafetynews.com/2011/01/pasteurization-protects-people-period/ by gradually heating a container with sprays of warm water. The temperature is raised in phases up until it reaches the needed pasteurization unit for the drink and then kept for the specified period.

Once the wanted time and temperature have actually been accomplished, the beer is cooled with showers of low-temperature water until it gets to ambient temperature level. https://www.prweb.com/releases/grower_direct_nut_company_obtains_almond_board_of_california_terp_approval_with_napasol_almond_pasteurizer/prweb15983999.htm makes certain that all microorganisms in the beer are killed and it can be safely saved in a sealed container.

Tunnel pasteurizers are developed to make sure that the temperature is equally distributed throughout the whole area of the container, assisting achieve regular outcomes. This can be challenging with various other heat treatment approaches such as flash pasteurization, however the specific temperature level control that Tunnel pasteurizers give can make all the difference for a brewery's procedures.

Ecological Influence

As beverage suppliers deal with boosting pressure to lower their carbon impacts, Tunnel pasteurizers are an useful tool for maintaining waste to a minimum. The system heats the container to an accurate temperature for a set period, getting rid of hazardous microorganisms without damaging the drink's physical stability or influencing its taste profile.

As an added advantage, Tunnel pasteurization likewise functions great with carbonated beverages-- including the prominent craft makes that so many beer enthusiasts love. It helps to expand their life span while protecting those complex jump keeps in mind that customers enjoy a lot.

A company lately retrofitted their Tunnel pasteurizer to use solar energy for heating up the liquid, which caused a 35% reduction of water usage. They have actually likewise carried out a closed-loop waste water treatment plant to further reduce their environmental effect even better. This shows just how essential sustainable methods are, and how they're important to satisfying consumer demand and eco-friendly responsibility. Keep tuned for future updates on all of the groundbreakings, project starts, ribbon cuttings and buildouts that are occurring around the country!

Getting Understanding Concerning The Benefits Of Using Skid Steer Machinery In Building And Construction Undertakings

Did you recognize that skid steer devices can change your building and construction tasks? With its flexibility and effectiveness, this equipment is a game-changer.

Whether you're dealing with a tiny household website or a big industrial task, skid steer tools can handle everything. Its portable size and ability to move permit you to browse tight areas and gain access to hard-to-reach areas easily.

And also, the variety of attachments offered for skid steer loaders gives you the versatility to take on different tasks, from excavating and grading to lifting and transporting.

So, if you're seeking to increase efficiency and enhance your building and construction jobs, it's time to take into consideration the advantages of skid guide equipment.

## Adaptability and Performance

Are you questioning why skid steer equipment is understood for its versatility and effectiveness on building and construction tasks? Well, let me tell you.

Skid guide tools is made to manage a large range of tasks, making it unbelievably flexible. Whether you require to dig, lift, press, or bring materials, a skid guide can do everything.

Its small dimension permits it to navigate quickly in limited spaces, raising its efficiency and efficiency. Furthermore, skid steers are furnished with effective engines and hydraulic systems that allow them to tackle durable work effortlessly.

They're likewise suitable with different add-ons, such as buckets, forks, and grapples, more improving their convenience.

## Compact Dimension and Ability To Move

When it comes to steering in limited areas, the compact size of skid guide devices is a game-changer. Right here's why:

1. Flexibility: The little size of skid steer tools permits it to browse via slim paths and confined areas that larger machinery can't access. This means that building jobs can be executed successfully, also in limited areas.

2. Easy Handling: Skid steers are created with exceptional ability to move, thanks to their portable measurements and special guiding system. This makes it simpler for drivers to turn, pivot, and change instructions easily, enhancing performance and decreasing the risk of crashes.

3. Less Damages: The small size of skid guide tools also lessens the possibility for property damages throughout construction projects. With better control and precision, operators can navigate around challenges without causing unneeded damage, saving time and money at the same time.

## Vast Array of Attachments

With a large range of accessories, you can easily customize your skid steer equipment for numerous building and construction jobs. This convenience is among the key benefits of using skid guide tools.

Whether you need to dig, raise, break, move, or quality, there's an add-on available to satisfy your particular needs. For https://www.forconstructionpros.com/equipment/attachments/lifting-material-handling/article/21427331/balance-cost-vs-productivity-when-selecting-pipe-laying-attachments , if you're servicing a demolition job, you can connect a hydraulic breaker to your skid guide to efficiently break down concrete and various other products.

If you need to clear particles or snow, you can affix a pail or a broom accessory. This versatility permits you to take on a wide variety of building and construction jobs with simply one tool, conserving you money and time.

## Final thought

So, why opt for anything less when you can have the best?

Skid guide equipment deals unmatched versatility and efficiency, allowing you to take on any type of building project effortlessly. Its small size and maneuverability make it a best choice for browsing limited rooms.

Furthermore, the wide variety of attachments readily available makes certain that you have the best device for each task.

With all these benefits, isn't it time you updated to skid steer equipment for your construction tasks?

Tips For Choosing The Ideal Attachments For Your Skid Steer Machinery

So, you've obtained a skid guide tools, huh? Well, congratulations! Currently comes the enjoyable component-- selecting the ideal accessories. Because, you know, having the wrong add-ons would just be too uninteresting. But anxiety not, dear skid guide owner, for we are below to direct you via this critical decision-making process.

In this short overview, we will certainly stroll you with the actions of recognizing your tools, examining your task needs, and inevitably selecting the perfect accessories that will certainly make your skid steer really beam.

So, bend up and prepare to take your skid guide to an entire brand-new degree of awesomeness. Allow's do this!

Recognizing Your Equipment

To effectively choose the ideal add-ons for your skid guide equipment, it's critical to have a solid understanding of its capabilities and limitations. Knowing what your devices can and can't do will certainly assist you make educated choices when choosing attachments.

Beginning by acquainting on your own with the requirements and weight restrictions of your skid guide. Consider elements like lift ability, hydraulic circulation rate, and auxiliary connections. Understanding https://www.digitaljournal.com/pr/increasing-applications-in-waste-management-sector-shaping-loader-bucket-sales-finds-fmi will make certain that you pick add-ons that are compatible with your devices and can be run safely.

In addition, examine the surface and tasks you'll be performing. Different attachments excel in various settings, so it is very important to match the add-on to the task available.

Assessing Your Work Requirements

Once you have a solid understanding of your skid steer equipment, it's time to analyze your job requirements. This step is important in picking the appropriate add-ons for your particular requirements.

To help you in this procedure, consider the following:

- Examine the nature of your projects: Figure out whether your work includes digging, training, grading, or any other details tasks that call for specialized attachments.

- Take into consideration the surface: Take into account the kind of surface you'll be dealing with, such as concrete, dust, or unequal ground, as this will affect the kind of attachment you require.

- Evaluate the range of your jobs: Establish the size and range of your tasks to guarantee that the add-ons you select are capable of managing the workload.

Picking the Right Attachments

Consider your specific demands and demands when choosing the appropriate add-ons for your skid guide devices. The secret to choosing the ideal accessories depends on recognizing the tasks you need to complete. Take into consideration the kind of work you normally execute and the conditions in which you run.

As an example, if you frequently work on building websites, attachments such as containers, grapples, and hydraulic hammers might be important. On https://www.cdrecycler.com/article/fecon-mulcher-skid-steer-matching-wood-recycling , if you're involved in landscaping, add-ons like brush cutters, tree spades, and soil conditioners may be preferable.

It's additionally crucial to think about the compatibility of the accessories with your skid steer. Make sure that the attachments you choose are specifically made for your equipment design and have the required hydraulic capability.

Final thought

So, there you have it! By understanding your skid guide devices, evaluating your job demands, and choosing the right accessories, you can make certain maximum productivity and efficiency in your work.

Don't underestimate the power of the best add-ons - they can be the secret to getting the job done swiftly and effectively.

Bear in mind, with the right tools, anything is possible!

Exactly How Tunnel Pasteurizers Extend Life Span Of Beverages

Pasteurization expands the shelf life of drinks by killing germs that create them to ferment or weaken.

Normally, beer and also various other non-dairy drinks are sterilized to a temperature level of 140 degrees or less. more resources is generally done by spraying hot water over cans or immersing them in hot water for a set time.

Batch Pasteurizers

Pasteurization is the process of home heating as well as holding a food product in order to make it secure for intake. It's an efficient method of preserving many kinds of items, including beer, milk, juice, soda, wine, and also extra.

For beer as well as drink manufacturers, pasteurization is a vital approach to standardize their products. It additionally helps ensure that they're able to preserve constant taste.

If your beer or beverage manufacturing has grown to the point where it's outgrowing your set pasteurizer, after that a tunnel pasteurizer might be the answer for you. This type of machine is made to manage numerous hectoliters at quick line rates.

VIDEO: “SINGLE & TRIPLE TEMPERATURE BATCH PASTEURIZERS”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) February 7, 2023

Video Summary Release for Brewmasters & Beverage Makers

Video Link: https://t.co/MtKLEqRlOt

Article Link: https://t.co/hvo1dHvyEK

PRO Engineering / Manufacturing Inc.

414-362-1500

When a pasteurizer is running continuously, it is essential to keep it tidy as well as without debris. This requires routine upkeep and also adjustment outs of the water that enters into it. It can also help to use ingredients to aid eliminate bacteria, odors, as well as other concerns.

Beer & Drink Makers

Beer as well as beverage manufacturers are constantly seeking to provide a distinctive preference with premium quality that customers can rely on. That implies concentrating on the quality of your pasteurization line, and enhancing that efficiency to guarantee product security.

Whether you are brewing, generating or packaging beer, soft drinks, energy drinks or functional beverages, Tunnel pasteurizers are an effective way to lower bacteria and prolong shelf life of your items. These makers function by splashing a mix of warm water and also heavy steam in several temperature zones to warm up the product up until it is sterilized.

This procedure is additionally utilized by non-alcoholic beer manufacturers, whose beverages are not subject to stricter laws than alcohol-based beverages. Yet just like various other product classifications, ambient temperatures can quicken the spreading of yeast as well as germs in non-alcoholic beers, creating them to create off tastes.

Compact Modular Pasteurizers

Companies that package products in bottles, canisters or jars use Tunnel pasteurizers to boost item security as well as prolong life span. These equipments have the ability to process big volumes of fill as well as cap products on a conveyor system while being sprayed or sprinkled with water to achieve drink particular pasteurization systems that eliminate germs.

Throughout the handling cycle, Tunnel pasteurizers split right into different areas for warm preservation, sterilization as well as pre-cooling. Depending upon the application, these areas can be controlled by PID managing pneumatic membrane layer managing shutoff or by regularity conversion rate law to achieve exact item temperatures.

This technique enables boosted control of the water temperature level in the specific zones, which minimizes the amount of water and energy intake. Furthermore, the water in the zones is conducted upwardly for scattering or splashing of the product to be sterilized through branching lines into a dispersing tube on the side opposing the zone pump.

Industrial Pasteurizers

A passage pasteurizer is a commercial pasteurization equipment that can be used to damage bacteria and enzymes on shaken, bottled, canned as well as secured beverages. They are available in a range of sizes, dimensions and technical specifications to fit your particular manufacturing requirements.

Throughout the process, bottles and cans are warmed to kill pathogenic microorganisms as well as inhibit enzymes, which prolongs service life. They are after that cooled down to the desired temperature prior to leaving the Tunnel.

In the beer market, Tunnel pasteurization is frequently made use of to make certain secure intake by ruining dangerous yeast and mold and mildews. However, the procedure can additionally affect the taste and also nutrient web content of beer and create staling, an accumulation of turbidity in the item.

To reduce the threat of over-pasteurization, Haffmans supplies trustworthy tracking tools that allows drivers to keep track of private temperature areas in a tunnel pasteurizer. simply click the next internet site in these zones are monitored to ensure that the product is not sterilized at temperatures too expensive for the sort of drink being processed.

Tunnel Pasteurizers Are Devices Utilized To Treat Food At Heats

This procedure boosts biological security of the product. visit the next post have added functions to aid you maximize the pasteurization process. For instance, some models have an automatic drier to get rid of drainage throughout the processing process.

Tunnel Pasteurizers are offered in different dimensions. You can purchase a large pasteurizer for large production centers, or a tiny one for a home cooking area. In general, a small Tunnel pasteurizer provides adaptable prices, lowering maintenance expenses as well as downtime. Most devices are made from T304 stainless-steel, as well as some can be outfitted with outside suction boxes for easier accessibility to the inlet screens. These boxes also stop particles from entering the pump mechanism. Additionally, these inlet screens can be changed on-the-fly, saving you time and money.

The temperature as well as time of flow of packages with a passage pasteurizer are established by the control board. This is an essential facet for computing the pasteurisation units. Numerous makers can save this details electronically. The operator panel is made from stainless-steel. It lies on the top of the equipment. It includes all the controls for the pasteurization procedure, consisting of the temperature level and also time. The temperature is additionally readjusted based upon the type of product being sterilized.

“PRO ENGINEERING TUNNEL WARMERS FOR BEVERAGE PACKAGING IN 2023”

— PRO ENGINEERING / MANUFACTURING Inc. (@Daveone1) January 31, 2023

Article Release for Brewmasters & Beverage Makers by Edward A. Michalski, CEO of PRO Engineering / Manufacturing Inc.

Full Article: https://t.co/iUYgZ8XiVT

PRO Engineering / Manufacturing Inc.

414-362-1500

Lots of suppliers incorporate an additional function to their pasteurizers, referred to as the Pasteurization Device (P.U), to determine the heat's impact on microorganisms. Throughout the process, an item undergoes 60degC for one minute. The temperature level of the item in the Tunnel is proportional to the Lethality (P.U.) of the product. The greater the temperature, the better the lethality.

Tunnel Pasteurizers enhance the shelf-life of a liquid by shutting off microorganisms as well as enzymes. These makers make use of innovative modern technology as well as energy-saving attributes. Some makers are modular, with deck dimensions of 5m2 to 500m2. They come with continuous belts made from polypropylene or stainless-steel. They can also be managed by a PLC. These devices can be made use of to sanitize drinks that come in a variety of styles, including tinned or iced up products.

Unlike flash pasteurizers, Tunnel pasteurizers do not require kegs. Due to the fact that they are not as large, Tunnel pasteurizers can be put on many different markets. please click the following post are additionally helpful for vegetables and fruit processing, as well as jams and sauces. The selection relies on the sort of item you're sterilizing, your goals, and the space readily available on the flooring.

The use of a passage pasteurizer gets rid of the danger of microbial contamination throughout the product packaging procedure. Tunnel pasteurizers have multiple temperature level areas to make sure that the temperature level can be gradually enhanced. This implies that a beer may reach the right PU without picking up a bacterial infection. Tunnel pasteurizers are normally utilized in the industrial developing market.

Tunnel Pasteurizers offer a straightforward and also reliable choice to blink pasteurization and also sterilized purification. They additionally do not damage the taste of foods as well as stop overpasteurization. They are readily available in a variety of sizes and also can be tailored to fit the firm's needs. There are even custom Tunnel pasteurizers available for special processing demands. The only disadvantage to making use of a passage pasteurizer is that they aren't affordable.

Tunnel Pasteurizers can be utilized in a range of industries. Some kinds of beer and also a glass of wine are not suited for all environments, as well as you must consider the type of product you're preparing. Several of these products need a higher PU than others. These sorts of beers can additionally be prone to spoilage organisms. So it's necessary to thoroughly pick your products for pasteurization to guarantee maximum quality.

The temperature variety of the procedure water ranges from 60 to 100 degC, as well as the size of the process depends on the sort of container utilized. Proper fittings are very important for the very best precision. You ought to constantly put determining points at the points of rate of interest when adjusting the equipment. In addition, you need to make sure the maker's temperature and also stress surveillance system is outfitted with sufficient channels.

Tunnel Pasteurizers Are Made Use Of To Securely Pasteurize Beverages To Increase Their Life Span

Tunnel Pasteurizers are utilized to safely and effectively process liquids and various other products for pasteurization. Tunnel Pasteurizers are made of stainless steel as well as have numerous zones for pasteurization. Each zone has its own set of spray nozzles and also drip frying pans to equally heat as well as cool down the item being pasteurized.

Tunnel Pasteurizers are made up of numerous sections with their very own blood circulation pump, collection sump, screen/filter box, as well as water spray system. If any of these parts falls short, the procedure may be jeopardized and might bring about issues with safety, process dependability, plan top quality, and also total price of possession.

Tunnel Pasteurizers have numerous benefits over flash pasteurization. For one, they are much less complex than flash pasteurization and also do not require various procedures for different kinds of beverages. https://www.foodsafetynews.com/2011/01/pasteurization-protects-people-period/ are usually made use of in the beer sector, but can additionally be made use of to pasteurize fruit and vegetable products.

Tunnel Pasteurizers are extremely reliable devices that remove microorganisms from food as well as beverage products. They are readily available in a range of dimensions, and also are used in the food and also drink industry to eliminate germs, quit fermentation, and also enhance shelf security. A number of elements add to the delicacy of these equipments, including substantial temperature level variations, caustic cleansing chemicals, as well as enormous mechanical tensions. Damaging containers, for instance, can seriously damage the tool. Fortunately, there are some makers who understand the need to preserve their items as well as can supply trusted solution.

A passage pasteurizer is an outstanding alternative for those who are searching for a quick, efficient, as well as affordable choice to flash pasteurization and clean and sterile filtering. Tunnel Pasteurizers can be personalized to match the needs of various business, and also are usually equipped with automatic quit devices to prevent overpasteurization. They can also be developed to fit particular size needs.

Here Are The Advantages Of Powder Coating

Unlike fluid paint, which is supplied via vaporizing solvent, powder Coating is applied as a free-flowing completely dry powder, then cured with warm or ultraviolet light. Powder Coating is related to surfaces in order to protect them from environmental damages and scrapes.

Pretreatment

Obtaining a superb pretreatment prior to powder Coating is a should to get a long-term, deterioration immune Coating. Along with enhancing the bond of the powder to the substratum, it likewise offers the steel with a safety layer.

The process can be a dip, spray, or a combination of several approaches. The selection of process depends upon the type of product being covered as well as the customer's requirements. The performance of the pretreatment should be matched to the requirements of the powder layer, along with the products utilized in the pretreatment.

The very first step in preparing a part for powder Coating is to eliminate surface dirts. Some usual methods include pressure washing, sandblasting, and sophisticated media blasting. The quantity of soil that needs to be removed will certainly vary relying on the kind of product being covered.

Electrostatic spray deposition method

Using electrostatic spray deposition, a powder blend is sprayed onto a metal surface. The electrostatic tourist attraction in between the powder particles as well as the metal surface area leads to a finish that safeguards the underlying material from corrosion. This Coating uses a selection of coatings as well as appearances. The Coating is additionally available in a variety of shades.

The electrostatic spray deposition procedure includes making use of an electrostatic spray gun and a powder spray booth. This system is an usual method of applying powder coverings. A corona spray gun is a common electrostatic spray gun. The electrostatic spray gun includes a nozzle that creates high voltage to develop an electrostatic field between the metal foil and also the spray mixture. The powder blend is after that sprayed via the nozzle to the steel surface area.

Fluidized bed powder Coating method

Unlike traditional liquid coverings, the Fluidized bed powder Coating technique is much more eco-friendly. It is additionally much less expensive. It provides a tough, smooth surface area with outstanding longevity. It can be put on various items such as metal superstructures, covering equipment, and aircraft parts.

Fluidized bed powder Coating technique is likewise made use of on various parts that undergo heats. It shields the part versus corrosion and also ecological effects. It likewise smooths over small details. During the process, components are preheated and after that dipped into a "fluidized bed" of plastic powder. Afterward, the parts are healed in an oven. This kind of Coating is optimal for get rid of Faraday cage effects.

Unlike liquid layers, the Fluidized bed powder approach creates heavy coats in one dip. This type of Coating technique has high transfer performance. It additionally gets rid of the requirement for overspray healing systems.

Recommended Reading -contamination

Making use of powder Coating to layer an item can be really effective. However, it is very important to use the right powder and to follow good contamination control techniques to ensure a top quality surface.

Cross-contamination takes place when a component or powder is exposed to impurities such as dirt, dirt, oil, and also steel chips. The end result might be a defect in the coating, which can cause a dissatisfied customer.

The smallest speck of dust might spoil a powder layered product. Consequently, it is essential to guarantee that the powder and also the air in the powder Coating space are clean. It is also essential to guarantee that the space is well filtered. This will certainly make certain that the dust from the remainder of the structure is unable to penetrate the powder Coating room.

Sturdiness

Amongst the many advantages of powder Coating is its resilience. It is utilized on a vast array of items. It provides resistance to impact, abrasion, deterioration, and chemicals. It can last for many years, even years, if it is used properly.

Powder Coating is additionally less destructive to the setting than traditional fluid paint completing. It launches negligible amounts of unpredictable organic compounds (VOCs) into the ambience. It is additionally simple to tidy. It is easily cleaned with lukewarm water.

https://www.european-coatings.com/articles/2022/08/ppg-invests-eur-11-million-to-double-powder-coatings-capacity-in-mexico offers a wide variety of structures, from smooth surfaces to rough appearances. It is also available in a range of finishes, from glossy to matte.

Powder Coating can stand up to smog, UV radiation, and acidic conditions. It is likewise extremely immune to corrosion, damaging, as well as weather. It can be applied to various sorts of products, such as metal, plastic, and glass. It is widely used in several industries, including building and construction, farming, electric engineering, and the production of mechanical parts.

This Short Article Aims To Supply An Intro To This Essential Topic Concerning Powder Coating

Unlike liquid paint, which is supplied by means of a vaporizing solvent, powder Coating is used as a completely dry powder and also cured with warm or ultraviolet light. It can be used on a selection of substrates, consisting of wood, steel, aluminum, fiberglass as well as plastic.

Electrostatic process

Established in the very early 1950s by a German scientist, electrostatic powder Coating is an ending up procedure that makes use of an electrical charge to adhere powder to metal. It can be used on lots of kinds of objects. Electrostatic coverings have numerous benefits over fluid as well as wet paint.

Electrostatic powder Coating is a sturdy coating that can be made use of on most metals. This method is likewise made use of to coat electrical components. It is a preferred technique for finishing external steel siding, yard furniture, and also cord shelving.

Electrostatic powder Coating uses a special maker to produce a static area on a surface area. It after that uses a dry powdered paint to the surface area.

Resilience

Utilizing powder Coating for your steel surface areas offers a hard, long-lasting finish that is resistant to rust, corrosion, chemicals, as well as influences. https://blogfreely.net/jared177albertine/here-are-the-benefits-of-powder-coating covered metal can last as long as twenty years.

Powder Coating likewise provides a smooth surface. The particles that comprise powder Coating have an electrostatic charge that attracts the steel. After the bits have actually bonded to the surface, they are baked in a stove at 400 degrees. This develops a durable surface that will certainly not peel or chip.

In addition to a long lasting surface, powder Coating is environmentally friendly. Unlike traditional fluid finishes, powder coverings do not contain solvents or contaminants. Actually, powder layers fulfill many environmental protection policies.

Eco-friendliness

Selecting eco-friendly items is essential to guarantee our world stays healthy and balanced. There are a number of options when it comes to paint, however powder Coating has the least impact on the setting. It also provides you a surface that will certainly last. It's easy to use and also is less costly than liquid paint.

Powder Coating is a process that makes use of finely ground fragments that are electrostatically charged to create a difficult coating. The Coating is healed in a specialized oven. https://squareblogs.net/randal2dion/here-is-a-more-detailed-take-a-look-at-what-is-powder-coating and will safeguard against scratches, UV rays, and weather condition direct exposure.

Cost-effectiveness

Contrasted to liquid Coating, powder Coating is a cheaper process. It is additionally a safer procedure, with fewer dangers as well as much less exhausts. The benefits of powder Coating can add up to substantial financial savings gradually. Furthermore, powder Coating can boost the quality of the coating and also save money and time.

One of the very best features of powder Coating is that it supplies superb deterioration protection. This means it is much less likely to rust during putting together, product packaging and also handling.

In addition, powder Coating can be used in a wide array of colors and structures. This enables better versatility in the finisher's application choices. It is also much less most likely to loosen up from the substratum than wet paint.

Applicability to non-metallic substratums

Utilizing powder Coating on non-metallic substratums can supply a variety of residential or commercial properties, including enhanced corrosion resistance, sturdiness, and also operational performance. These finishes can be applied in a variety of appearances and shades, and also are developed for ornamental, protective, and useful applications.

Using powder Coating on non-metallic surface areas requires using the Coating powder to the substrate in an uniform way. If https://www.european-coatings.com/articles/archiv/sherwin_williams-opens-new-powder-plant-in-poland is not used evenly, the substrate might expand or reduce, warp, or form issues on the ended up surface area.

Non-metal substratums include ceramics, timbers in all-natural or engineered kinds, and glass. Commonly, these surfaces are machined to create designs and forms. The substratums may also be transmitted. The final surface might vary from matte to shiny, depending upon the application.

Pretreatment equipment needed

Utilizing the right pretreatment devices is necessary to taking advantage of your Coating procedure. The tools must be developed to match your requirements as well as efficiency demands. As an example, you'll need to see to it that your water quality is of high quality to ensure that your powder Coating procedure achieves success.

The primary step in preparing a surface for powder Coating is cleaning up. Cleansing removes soils and also other surface area contaminants to ensure that your powder Coating is bonded effectively.

Some common cleaners include acids and also solvents. Nevertheless, you'll also need more powerful methods to eliminate impurities that are immune to the typical cleaners.

Downsides

Compared to wet paints, powder Coating is a lot more sturdy as well as supplies a durable coating. Powder Coating is likewise extremely environmentally friendly as it does not release unpredictable organic compounds (VOCs) right into the air. These gases are damaging to the air top quality. Powder Coating is also a lot more immune to scrapes and damaging.

In addition to the benefits of powder Coating, there are also some negative aspects. A few of these include the high startup prices, high lead-time as well as problem in color matching. However, powder Coating is rapidly growing in popularity due to technical improvements.

This Post Talks About The Advantages Of Powder Coating

Utilizing Powder Coating on an automobile will certainly provide the auto a lovely, glossy surface. This kind of Coating is used as a completely dry powder as well as is after that cured with warmth or ultraviolet light.

Electrostatic spray deposition approach

Whether you're looking for a high-performance Coating or a cost-efficient alternative to fluid paints, you can find an electrostatic spray deposition method that matches your needs. The technique works by applying a layer of powder to a metal substrate. It can be utilized to coat pipelines, as an example, for boosted resilience.

Contrasted to liquid applications, electrostatic spray deposition is a lot more long lasting as well as a lot more cost-effective. While conventional damp painting can leave you with an irregular surface, this method leaves your components smooth as well as shiny.

This process requires using a specialized spray gun. It likewise makes use of pressed air to press the powder through the gun and out of the nozzle. This air moves the powder along at a high price as well as atomizes the powder. It is additionally a great means to prevent clumping.

Unlike typical wet paint, powder Coating likewise doesn't require a solvent. It likewise supplies a variety of surfaces as well as structures. This approach can be made use of on a range of substratums, consisting of non-metallic products such as plastics.

Fluidized bed system

A number of industries depend on fluidized bed powder Coating to coat steel components. This Coating supplies a thick layer of protection versus wear as well as corrosion. The process involves warming the component as well as dipping it into the fluidized bed. The part after that relocates to a lower temperature level oven for curing.

Throughout the process, an operator needs to pay attention to the speed of the line and also the temperature of the component. This is required to preserve uniform application of powder. It is additionally important to keep in mind that the Coating thickness is dependent on the temperature level of the component and the duration it spends in the fluidized bed.

Electrostatic fluidized beds are especially suited for constant Coating of small basic arrangement parts. This kind of Coating requires high dielectric strength as well as film density control.

Electrostatic fluidized beds are also suitable to continual Coating of cable displays. The electric field stamina of these coverings is reduced. This makes them preferable for coatings that require much less air flow and also far better performance in Faraday cages.

Variations in between liquid paint as well as powder coat

Regardless of the differences between liquid paint and powder coat, both completing methods are made use of by markets for comparable applications. Both are utilized to protect steel surface areas from oxygen and also flying particles.

The distinctions between both are primarily connected to the application methods. Both approaches can leave smooth coatings on a surface area, yet there are numerous benefits to choosing one over the other.

Powder Coating is extra long lasting and lugs a reduced carbon footprint than liquid paint. It likewise gives a number of wellness benefits. It is likewise less complicated to apply. Powder coatings are typically without unstable natural substances (VOCs) and also can create thicker layers than liquid finishings.

Powder coatings additionally use a variety of specialty effects. Recommended Internet site of these results consist of pearlescents, flip-flops, and dormant pigments.

The major distinction between powder and fluid paint is that powder Coating is used as a completely dry powder, which suggests that the shade does not discolor. The color of a powder coat will certainly vary depending on the polymers used to make it.

Resilience

Depending upon the type of Coating, powder Coating can last anywhere from fifteen to twenty years. It is utilized on a range of surfaces consisting of steel, fiberglass, and some plastics. This long lasting surface protects versus the climate and also chemicals, which makes it particularly valuable in the building market.

Powder Coating gives a high-grade surface that is immune to deterioration. The Coating will certainly not chip or peel, and also the colors will certainly remain brilliant as well as vibrant for longer than standard damp painting. It is likewise long lasting and also will withstand bumps as well as flexing without peeling.

Powder Coating is much less dangerous to the setting than conventional fluid paint ending up. It creates really little hazardous waste as well as launches negligible quantities of volatile natural compounds (VOCs) right into the environment.

Powder Coating can be made use of to repaint house items, along with outdoor items like furniture. It can likewise be made use of to safeguard building and construction equipment and machinery. It is an economical coating that is durable and will last for many years to come.